What is traceability?

Traceability means being able to uniquely identify every part inside and outside of production at any time. Our solution differs from conventional methods as it does not require marking and is tamper-proof.

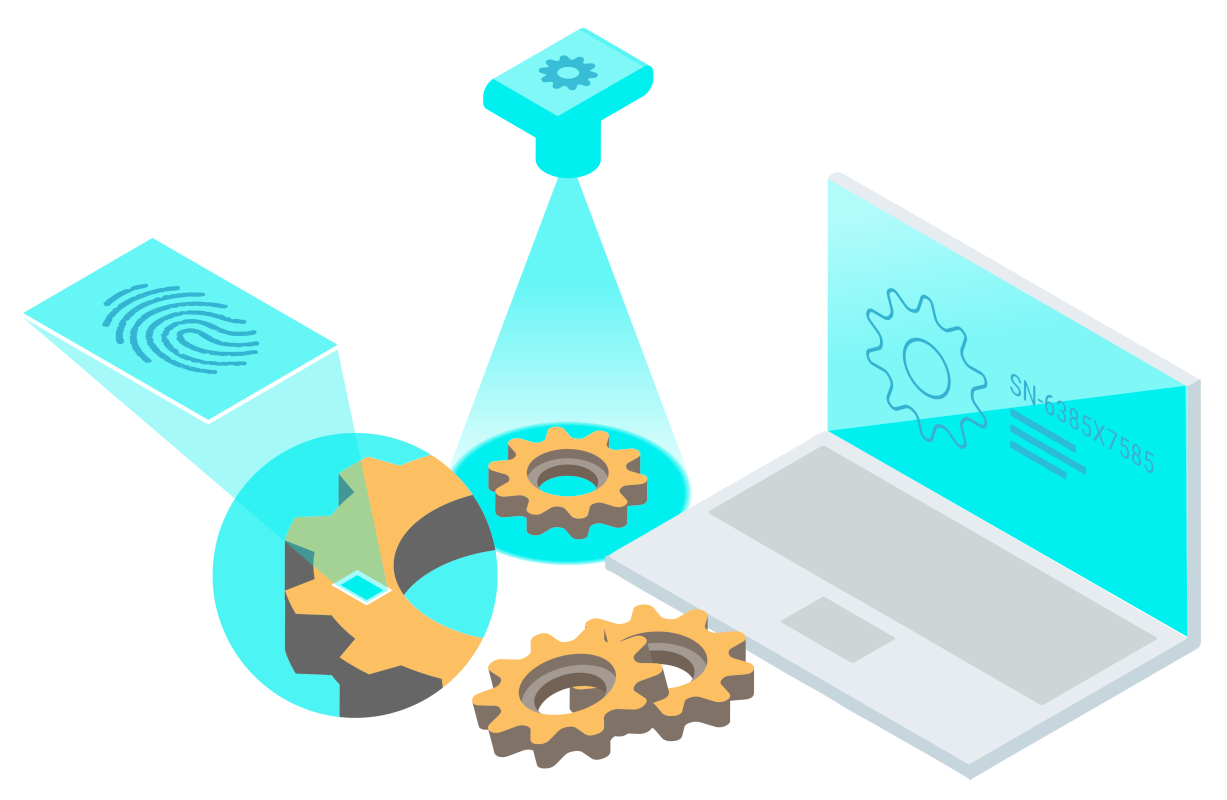

The digital fingerprint. Makes things easier.

Instead of applying a marking, we use natural surface patterns on the components. Our IRIS software uses this to create a digital fingerprint that can be used to uniquely and forgery-proof identify each part.

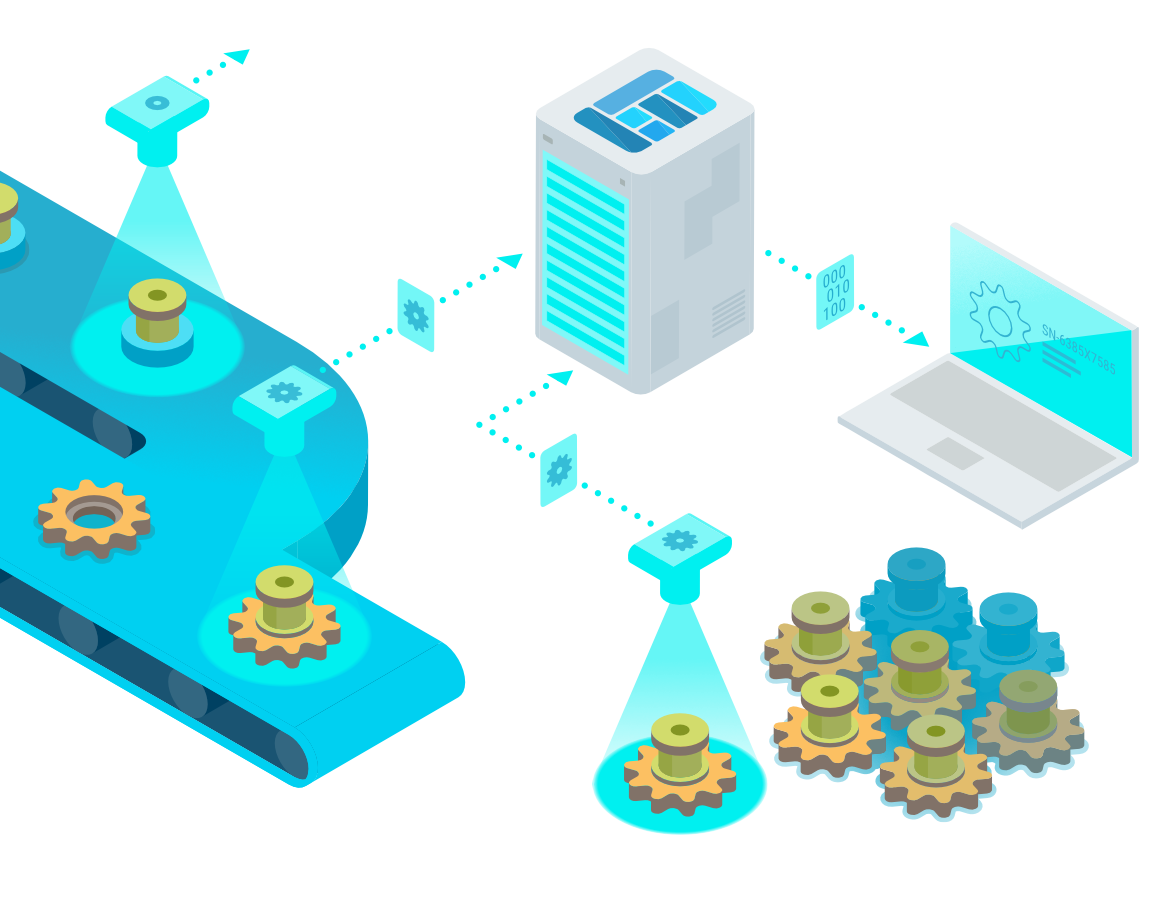

Integrated in no time

All you need to use our traceability solution are standard industrial cameras. The data is processed on-premise or in the cloud. The IRIS software can be easily integrated into existing systems via our API.

A powerful team

We are a young team with a clear goal: to establish a new, simple and more flexible traceability solution on the market. We offer our customers a perfect mix of expertise, inventiveness, determination and curiosity. This enables us to always adapt our product precisely to the wishes of our customers.

Kontakt

Are you interested in using our Tagless Traceability in your production? Then get in touch with us. We will be happy to provide you with advice on your application.