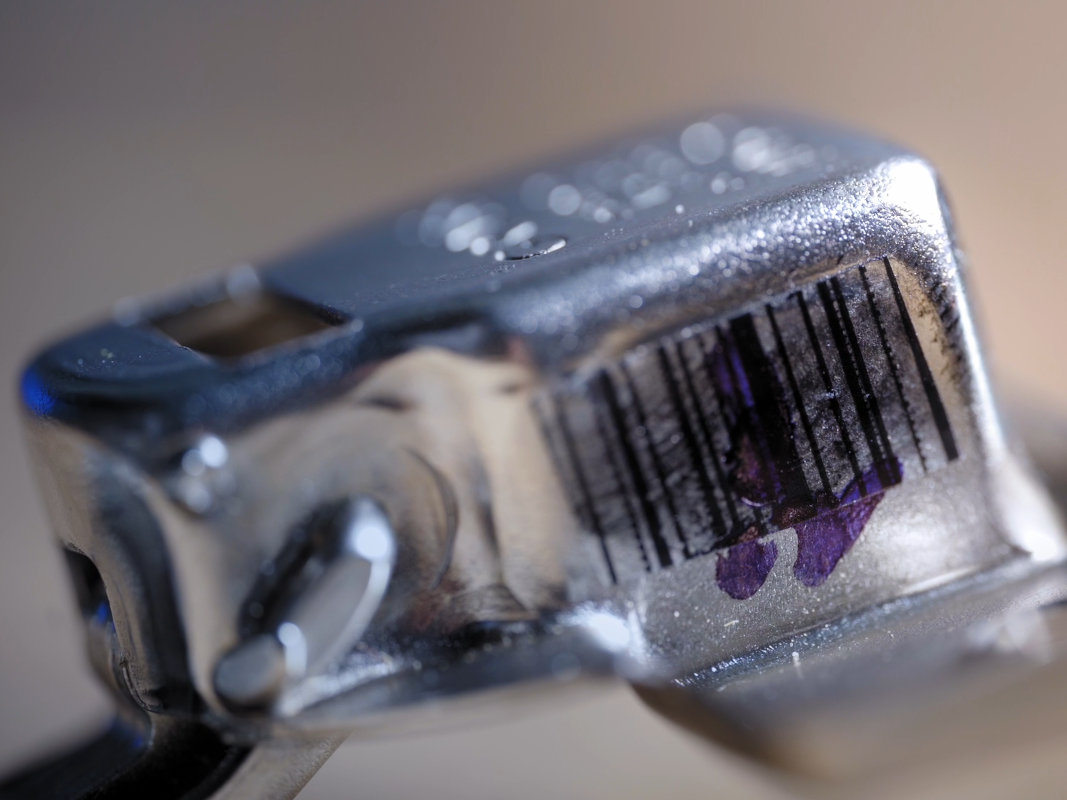

Photograph instead of Marking

When implementing traceability in a production line, marking methods like barcode, QR code or DMC are often chosen. This marking is usually applied directly onto the part or product using methods such as direct printing, labeling, needle engraving, or laser marking. However, this causes problems in the application:

- Unreliability with poor contrast or smearing print

- Cycle times too short, especially for laser marking

- High maintenance expenses and complex work safety (dust, dirt, noise, laser light)

- Often cannot be used for small, porous or filigree parts

- Complex integration and high investment costs

Traceability can therefore often not be implemented either technically or economically, even though it would bring great benefits for production.

Multiple advantages

Compared to conventional systems, Detagto's marking-free traceability system is significantly faster and requires less emissions and maintenance. In addition, the choice of identification area is much more flexible.

| Laser-marking | Tagless Traceability | |

|---|---|---|

Speed (per part) |

> 2-3 seconds | < 0,5 seconds |

| Emissions | Laser light, smoke/dust | Flashlight (harmless) |

| Product modified | Yes (engraved, min. 1 x 1 cm) |

No (Surface photo only, min. 0.1 x 0.1 cm) |

| Forgery-proof | No | Yes |

| Maintenance expenses | High (Replacement laser head, mechanical maintenance, |

Low (Lens cleaning, calibration) |

Simple installation, even in existing production

When retrofitting traceability into existing lines, flexible systems are required. This is where Detagto's marker-free system comes into its own. However, customers also benefit from the system's simple installation for new installations:

- As the component is not modified, no new approval or release is required

- The necessary camera boxes are very compact and can be easily integrated

- No additional hardware (e.g. suction or housing) necessary

- Tagless traceability can be easily connected to automation tools, machines or software systems via various interfaces

Kontakt

Are you responsible for setting up traceability within production and are not satisfied with the established technologies? Then get in touch with us! We would be happy to discuss your use case with you and show you the possible advantages of Tagless Traceability.